EMI Shielding Products

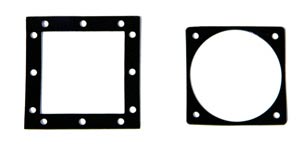

- Custom Gasket Fabrication

- Connector Gaskets

- Bonded O Ring

- Custom Gaskets

- Conduct-O-Knit Knitted Wire Mesh

- Conduct-O-Seal Combo Gasket

- Conduct-O-Elastomer

- Conduct-O-Seal Oriented Wire in Silicone Gasket Material

- Conduct-O-Mesh Tape

- Conduct-O-Foam

- Conduct-O-Bond

- Optical Filters For Electronic Displays

- Shielded Vent Panels

- 300 Series

Does Material Selection for EMI Shielding Matter?

The design process of creating EMI shielding enclosures is vitally essential to get right. Any issues or mistakes that are not caught in the design process end up causing performance issues. Reconfiguring devices that have already been produced and shipped comes at a significant cost to a company. Catching issues as they are small, or better yet, avoiding them altogether is the best way in which to design EMI shields.

Below, we would like to highlight several important considerations all engineers should make when looking to create the perfect EMI shielding enclosure.

The material consideration is the most critical aspect of designing an EMI shield that effectively works. Engineers have several material choices, and each one provides distinctive characteristics. Typically, copper, nickel, silver, and aluminum are the most used materials. Besides considering the performance characteristics of your material, you also must consider the cost. For instance, silver is an incredibly efficient and effective shielding material, but it is costly. Although price should be a factor in your consideration, it should not allow you to sacrifice effective characteristics. When silver is too expensive, graphite often becomes the secondary choice. It does not cost as much, but cost reduction also reduces shielding effectiveness.

The difference between compression stops and grooves is enough to distinguish between the two. Traditionally, grooves were a terrific way to manage FIP EMI gaskets. When EMI is dispensed into narrow grooves, it often causes liquid gasket material to cure the end effectively. This often results in an ineffective shield because of an imperfect seal. Compression stops allow designers and engineers to not worry about this issue, so when you can, choose compression stops over grooves in your EMI enclosure design.

Related Reading about EMI Shielding

- Integrated Circuits Have Problems with EMIWhen working with integrated circuits, EMI is always an issue that must be dealt with. Integrated circuits work in conjunction with circuit boards or heatsinks, and this causes cable to radiate.

- Understanding how EMI Shielding Works

- What are the Differences Between Radiated and Conducted EMI